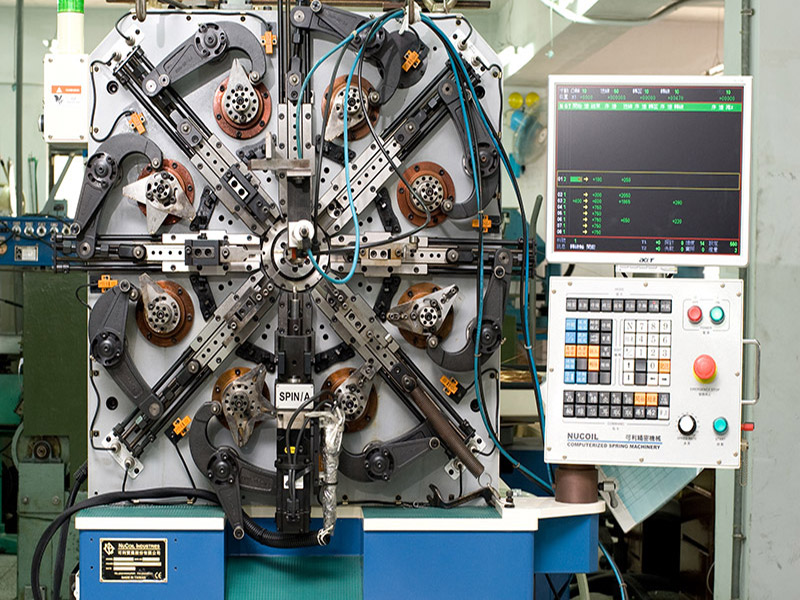

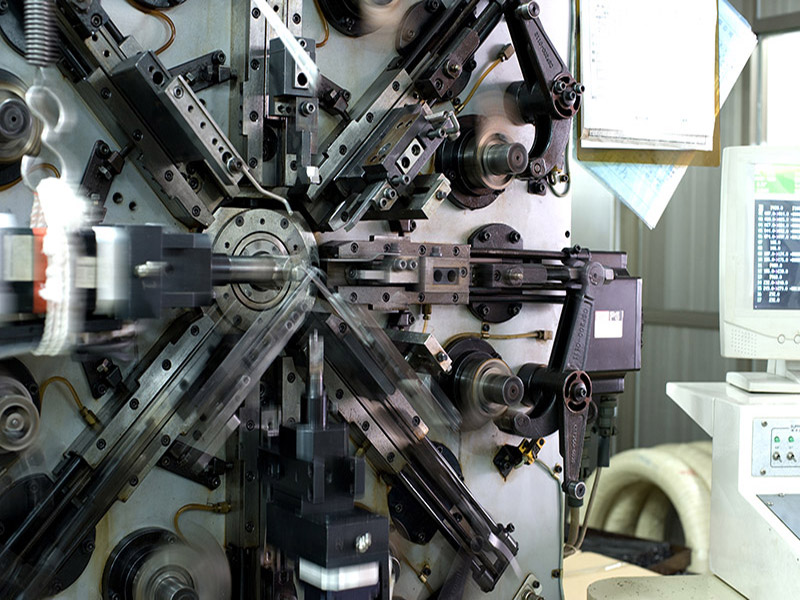

Wire Coiling

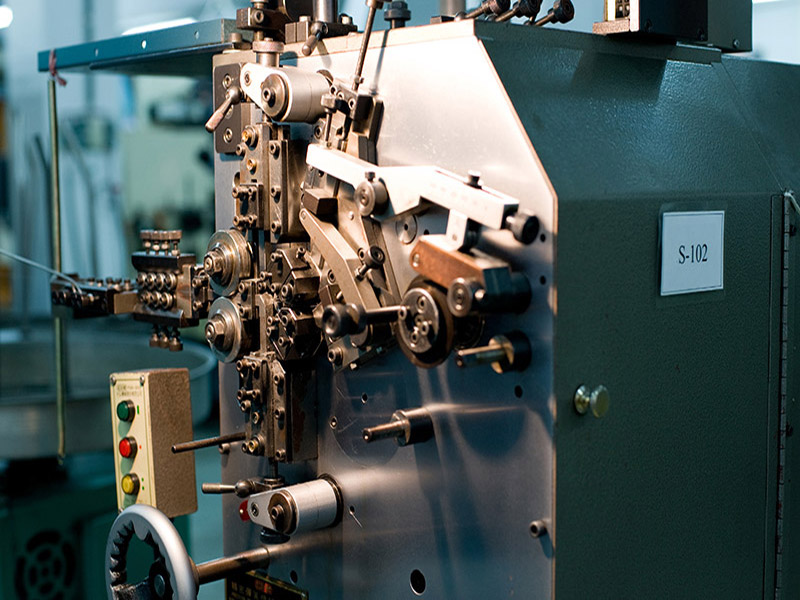

Hwa Ying commitment to technological innovation has enabled us to implement CNC spring coiling in every different size of wire. CNC coiling technology allows Hwa Ying to coil springs more quickly, with greater precision, and in a variety of profiles. Reduced set up time allows Hwa Ying to accommodate a variety of order sizes including large production orders to small prototype orders.

Hwa Ying’s array of capabilities allows us to customize to individual customer needs:

- Heavy compression springs of all sizes

- Heavy extension springs

- Heavy torsion springs

- Special end forming capabilities that include hooking, plugging and special requirements

- Specialty assembly capabilities to meet customer requirements

- Painting and a variety of specialty coatings

Many of Hwa Ying’s springs are used in:

- Automotive

- Commercial building dock levelers, door hardware and controls

- Construction equipment and vehicles

- Lift gates

- Heavy equipment anti-vibration mountings

- Industrial equipment

- Marine products

- Semi-truck brake systems

- Stamping presses (complete die spring line)

As one of the most efficient energy storage devices available, helical compression springs are the most common spring configuration in the marketplace today. From automotive engines to major appliances, they are found in countless applications.

Though, they are typically manufactured from round wire in a cylindrical shape, compression springs are extremely customizable. Square, ovate, rectangular and other non-round cross section wire can be fashioned to meet differing requirements. Additionally, the spring can be altered to conical, hourglass or barrel shape among other profiles. In this way, dynamic resonance conditions or height restrictions can be addressed. Variable pitch between the coils provides different spring rates throughout the operating range of the spring and aid in minimizing resonate surging and vibration. Because of the number of compression spring characteristics that can be tailored to specific circumstances, this type of spring represents a flexible design approach to force resistance and energy storage.

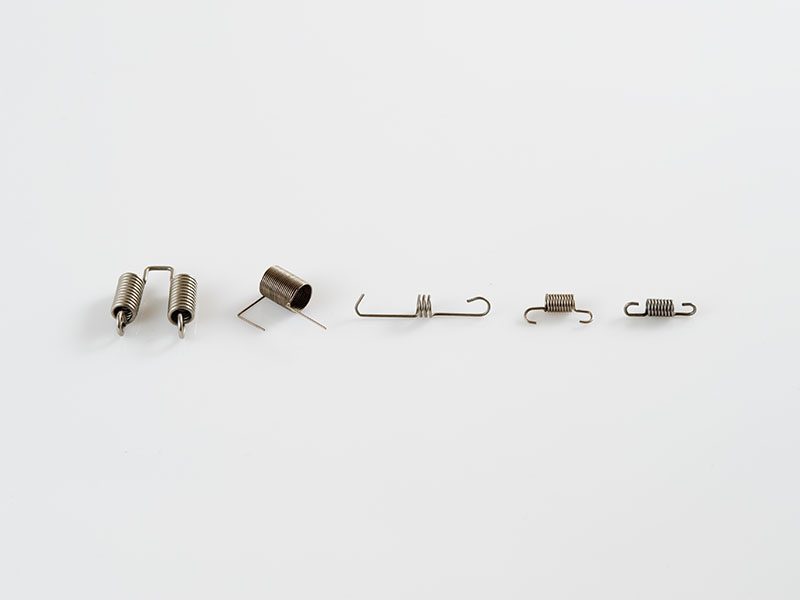

Helical extension springs store energy and exerts a pulling force. Extension springs differ from compression springs in that they do not have a solid stop to prevent overloading. For this reason, they are designed with lower stress levels. Typical applications include balance scales, trampolines, garage doors, dock levelers, farm machinery and various types of spring tensioning devices. Extension springs come in a wide array of sizes from small medical devices to off-road machinery brake springs.

In order to be a part of an assembly, extension springs require a method of attachment. Threaded inserts, swivel hooks, twisted loops and side loops are just a few of the nearly limitless options available. At the design stage, the length and positioning of the hooks at each end of the spring can be adjusted in order to obtain exactly the required spring load at any extended position. Silencers can be used to prevent vibration within the spring itself as well as eliminating noise in the application without upsetting the function of the spring.

Hwa Ying specializes in extension springs, using state of the art machinery and world class engineering. Our corporate laboratory, as well as individual plant testing facilities, allows us to fully serve every customer with superior manufacturing, testing data, and metallurgical documentation.

Helical springs used to apply a torque or store rotational energy are commonly referred to as “torsion springs” and are typically found in single-and double-bodied forms. Everyday uses include clothespins, ratchets, counterbalance mechanisms, and as a coupling between concentric shafts such as in motor and pump assembly.

Cost-conscious torsion springs implement round wire. When the situation calls for higher performance, rectangular or other non-round wire can be substituted to improve efficiency and obtain higher energy storage capacity. Space between the coils can also be designed to reduce friction. In a case of extreme torque, two separately-designed coil sections – one with a right-hand twist and the other left-handed – can be connected together creating a double-bodied spring. This allows the total torque to match the sum of the two coils combined. Various kinds of ends including short hook, hinge, straight and customizable are available to facilitate mounting.

At Hwa Ying, we not only design, manufacture, and test these springs, we are customer focused to ensure clients are matched with the proper device to suit their needs.

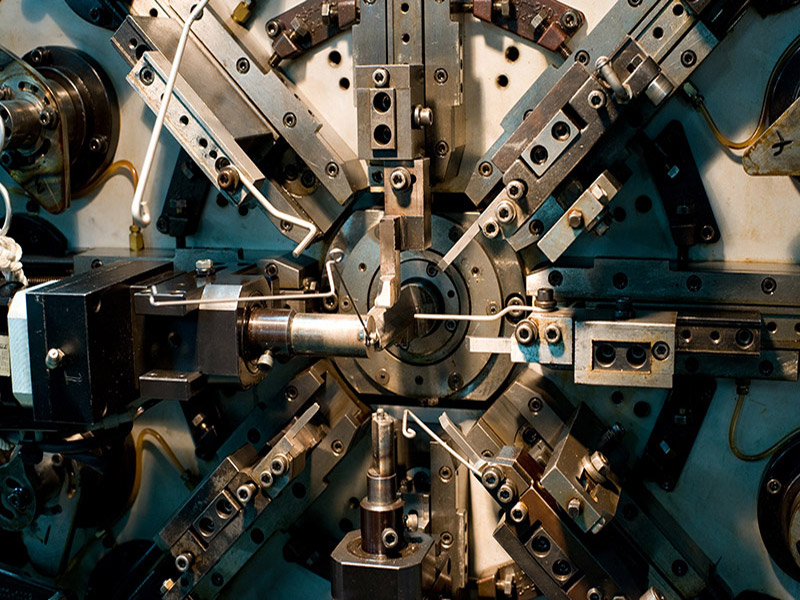

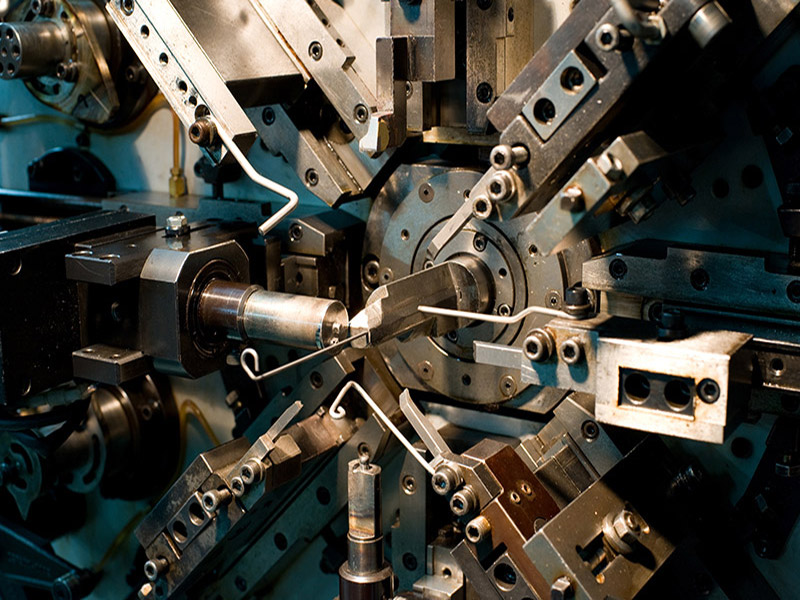

Much like springs, flat springs and wire forms are generally fashioned from round wire or strip material, then bent into shapes engineered to meet a specific task. Rather than employing a coiled body, wire forms rely on angles and lengths to provide resistance and support. Hooks and bends often act as attachment points for the device.

Leaf, beam and cantilever are the most common flat springs. Hwa Ying have the state of the art multiform equipment necessary to shape forms for nearly every application.